Your production expenditure involves indirect expenses needed for manufacturing but is not limited to specific production creation. It includes the corporation’s rent and utilities, quality control and inspection charges, equipment maintenance charges, and indirect labor wages. Understanding your company’s finances is an essential part of running a successful business. That’s why it’s important to get to know all of the different terminology relating to accounting, and how these financial metrics can be used to assess the financial health of your business. Overhead costs are recurring cash outflows required for a company to remain open and “keep the lights on.” However, overhead costs are not directly tied to revenue generation, i.e. indirect costs.

Steps to Calculate Predetermined Overhead Rate

Whether you’re running a small shop, bidding on contracts, or managing production in a larger firm, you’ll see why this tool matters. In this guide, I’ll show you the formula, how to pick the right base, and a few Statement of Comprehensive Income simple examples to make it click. But its power to provide timely product cost information for pricing and decision-making is indispensable. Think of it as applying a standardized slice of your indirect costs to every single thing you produce.

How to Calculate Predetermined Overhead Rate

- Using the predetermined overhead rate formula and calculation provides businesses with a percentage they can monitor on a quarterly, monthly, or even weekly basis.

- These rates can be calculated using predetermine overhead formula by using estimated manufacturing overheads and estimated units of production or other valid basis.

- This ongoing evaluation and refinement process helps maintain the effectiveness of the predetermined overhead rate.

- When monitoring and controlling overheads, businesses need some standard, to compare actual overheads with, to understand whether the budget is being properly followed.

- Common activity drivers include machine hours, number of service calls, kilowatt-hours used, square footage, number of employees, and hours worked.

- Before jumping to detail, let’s go through the basic overview and key definition first.

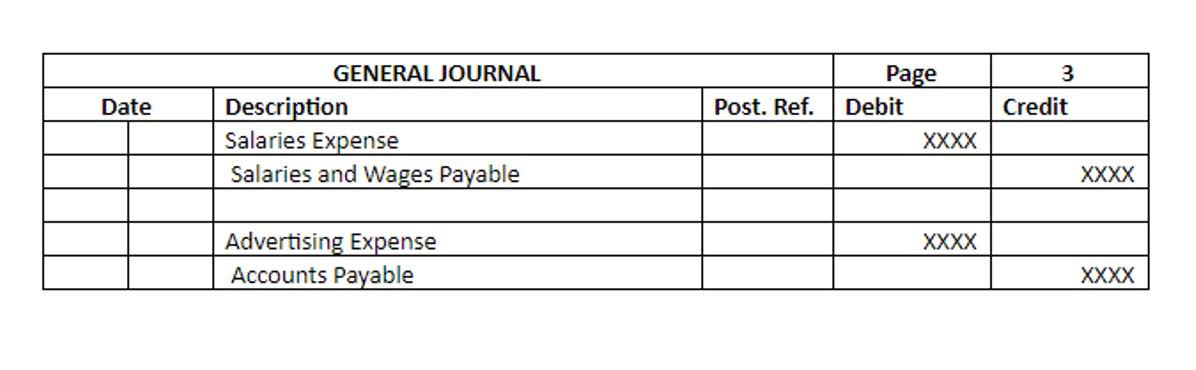

By inputting basic cost and activity data, Sourcetable’s AI assistant instantly computes the overhead rate using the formula Total Estimated Overhead Costs / Total Estimated Allocation Base. This critical financial metric is vital for accurately assessing product costs or services. If the rate was calculated at $50 per direct labor hour, a job requiring 150 actual direct labor hours will be charged with $7,500 in applied overhead. This applied amount is recorded as a debit to the Work-in-Process (WIP) Inventory account on the job cost sheet.

Setting pricing

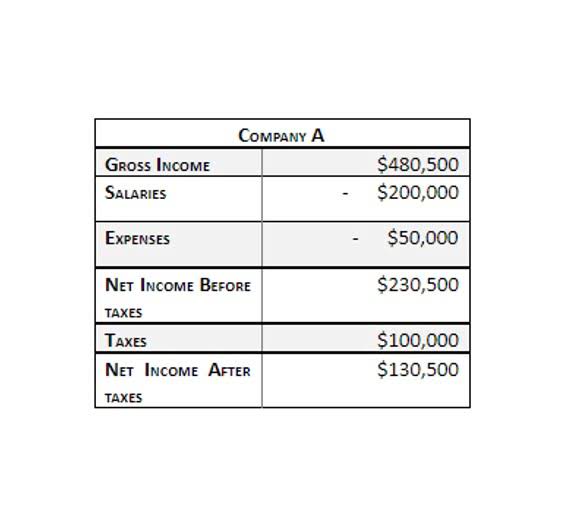

Tracking any differences between applied and actual overhead also allows companies to improve future overhead estimates. By using the predetermined rate product costs and therefore selling prices can be calculated quickly throughout the year without the need to wait for actual overheads to be determined and allocated. In addition while manufacturing overheads might vary seasonally throughout the year, the use of a constant predetermined rate avoids a similar variation in unit product cost. In order to estimate the predetermined overhead rate it is first necessary to to decide on an activity base normal balance on which to apply overhead costs to a product. Sales of each product have been strong, and the total gross profit for each product is shown in Figure 6.7.

One of the advantages of predetermined overhead rate is that it can help businesses monitor overhead rate. This comparison can be used to monitor or predict expenses for the next project (or fiscal year). The estimated manufacturing overhead cost calculating predetermined overhead rate applied to the job during the accounting period will be 1,450. If the job in work in process has recorded actual material costs of 4,640 for the accounting period then the predetermined overhead applied to the job is calculated as follows.

- The key is to select an allocation base that has a logical relationship with your overhead costs.

- In this article, we will cover how to calculate the predetermined overhead rate.

- For example, let’s say the marketing agency quotes a client $1,000 for a project that will take 10 hours of work.

- At the end of the accounting period, you’ll have a difference (called a variance) between your applied overhead (using the predetermined rate) and your actual overhead costs.

Breaking Down the Predetermined Overhead Rate Formula

Activity-based Costing leverages overhead expenses for certain company activities. You can optimize your pricing strategies and functionalities with precise estimated overhead expenses. By following these steps, manufacturers can effectively allocate overhead costs and establish accurate cost estimates for their products. Companies use predetermined overhead rates to close the books, monitor relative expenses, monitor the overhead rate, and set pricing. These costs are allocated based on the level of activity or resource consumption.

There are many reasons why businesses need to calculate predetermined overhead rates, although, they may have some limitations. The predetermined overhead rate allocates estimated total overhead for an accounting period across expected activity or production volume. It is calculated before the period begins and is used to assign overhead costs to production using an allocation rate per unit of activity, such as direct labor hours. The formula seems simple – total overhead costs divided by an allocation base like direct labor hours. However, accurately calculating overhead rates involves breaking down costs and choosing the right allocation base. Calculating predetermined overhead rates is critical for accurately assigning manufacturing costs to products.

- Accumulating these figures requires forecasting based on expected production volume, known contracts, and historical spending patterns.

- The elimination of difference between applied overhead and actual overhead is known as “disposition of over or under-applied overhead”.

- If the allocated manufacturing overhead of your corporation will have a high proportion of fixed expenses compared to variable expenses, you may struggle with financial functionalities.

- It includes raw material storage fees, utilities and energy expenses, and shipping & logistic expenses such as packaging, transporting, delivery, etc.

- Specifically, the predetermined overhead rate is an approximated ratio of manufacturing overhead costs determined in advance based on variable and fixed costs.

Actual Overhead

That is, a predetermined overhead rate includes the ratio of the estimated overhead costs for the year to the estimated level of activity for the year. Using a predetermined overhead rate allows companies to apply manufacturing overhead costs to units produced based on an estimated rate, rather than actual overhead costs. This rate is then used throughout the period and adjusted at year-end if necessary based on actual overhead costs incurred.